“The staff believes these revisions will better risk-inform and improve efficiency and effectiveness of the program while still providing assurance that the cornerstone objectives are being met.

Staff also recommended extending the intervals between problem identification and resolution (Pl&R) inspections from every two years to every three years. Specifically, it proposed to eliminate IP 71124.02, “Occupational ALARA Planning and Controls,” from the radiation protection inspection program. NEI noted that the changes would clarify “the communication aspect of the color and eliminates color definition overlap that is confusing and sends a message that there is only a broad understanding of the significance rather than a true understanding of a more precise characterization of significance.” Fewer Inspections AheadĪlso important are proposed staff changes to sample sizes and resource estimates for several baseline inspection procedures. However, it did not change the Green and Red labels. Perhaps most notable are changes to the qualitative descriptions of a White inspection finding from “low-to-moderate” to “low” safety significance and to change the description of a Yellow inspection finding from “substantial” to “moderate” safety significance. Changes to White and Yellow Descriptionsīut in recommendations to the commission this June that NRC staff crafted after weighing stakeholder feedback, it chose a narrower focus in areas concerning assessment, inspection, and emergency preparedness. The NEI also urged the NRC to reduce “unproductive impacts” to White findings to resolve challenges to the licensing basis to open up communication about inspection issues, and significantly, to reduce baseline inspection hours and simplify the mitigating systems PI.Īs part of “high priority” recommendations, it urged the NRC to get rid of the press releases for White findings, reduce the burden of radiation protection and emergency preparedness inspections, eliminate materials inspections of independent spent fuel storage installations, and establish a process to resolve the “very low risk” questions about the licensing basis. The significance of White findings are “low-to-moderate” Yellow are “substantial” and Red are “high.” White, Yellow, and Red findings require that the NRC conduct supplemental inspections.

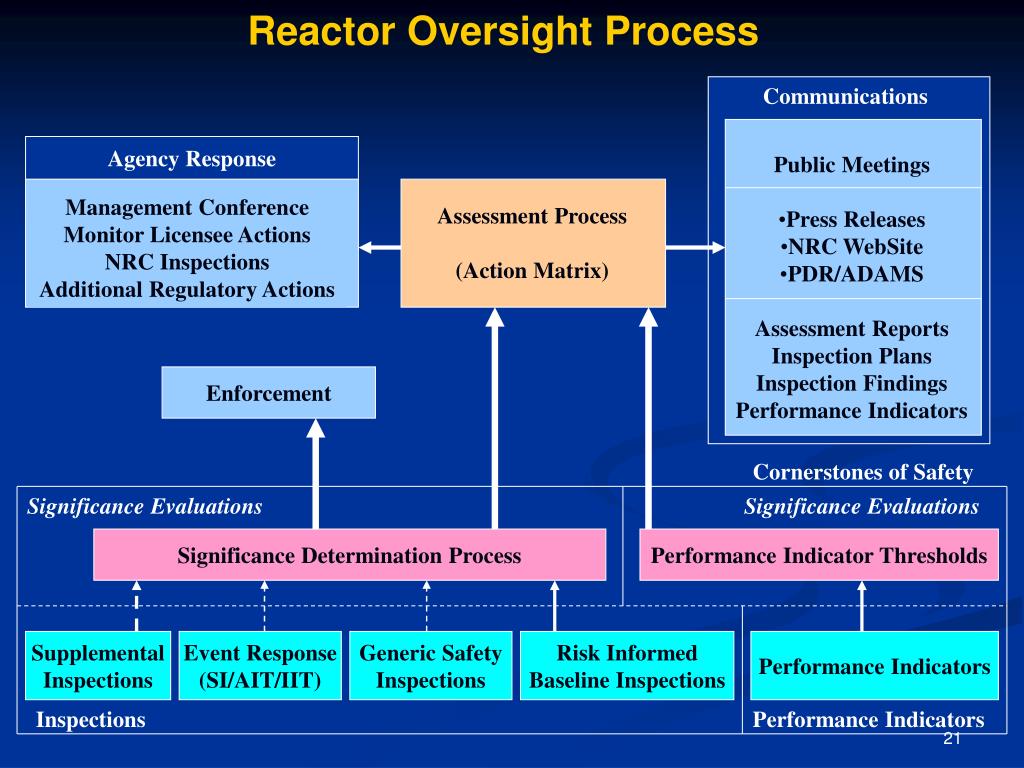

The NRC also tracks the ROP through an “action matrix”-essentially a graded approach that the agency uses to respond to performance issues.Ĭurrently, Green inspection findings suggest a “very low safety or security significance” and that the NRC’s cornerstone objectives are fully met. In that time, the sector has also improved safety margins through shared learning and best practices, improved risk assessments, and made more decisions that are informed by risk.ĭuring the ROP process, NRC inspectors generally implement inspection procedures, and nuclear plant operators report performance indicator (PI) results to the NRC. power reactor fleet has matured, accumulating more than 4,000 reactor-years of operating experience.

The trade group suggested 27 recommendations, though it stressed in a September 2018 letter to the NRC, that the ROP, established 20 years ago, remains sound, and it has helped in “incentivizing good performance.” The NEI also noted that while the ROP has evolved in response to operating experience, the U.S. Only a handful of those recommendations, however, came from the Nuclear Energy Institute (NEI), a trade group whose members include nuclear plant operators, reactor designers, fuel suppliers, and service companies. Its recommendations were narrowed into specific action items that staff published in a June 28 “notation vote,” a document that the NRC made public this week. The recommendations stem from a January 2018 memorandum from the NRC’s executive director of operations that tasked staff with identifying “potential transformational changes” to the NRC’s “regulatory framework, culture, and infrastructure to further enhance effectiveness, efficiency, and agility in regulating novel technologies.” To carry out the task, a “Transformation Team,” solicited feedback from internal and external stakeholders. In a bid to enhance the reactor oversight process (ROP), staff at the Nuclear Regulatory Commission (NRC) has recommended the commission change qualitative descriptions for some color labels that signify risk, scale back on the time and scope of some annual inspections at the nation’s nuclear power fleet, as well as increase intervals between inspections.

0 kommentar(er)

0 kommentar(er)